Importance of Pressure Testing: Ensuring System Integrity and Safety through Pressure Tests

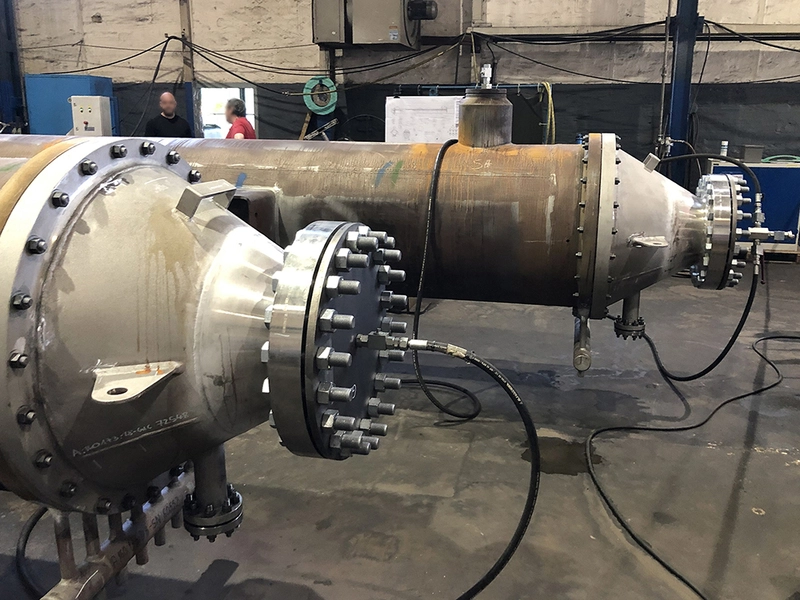

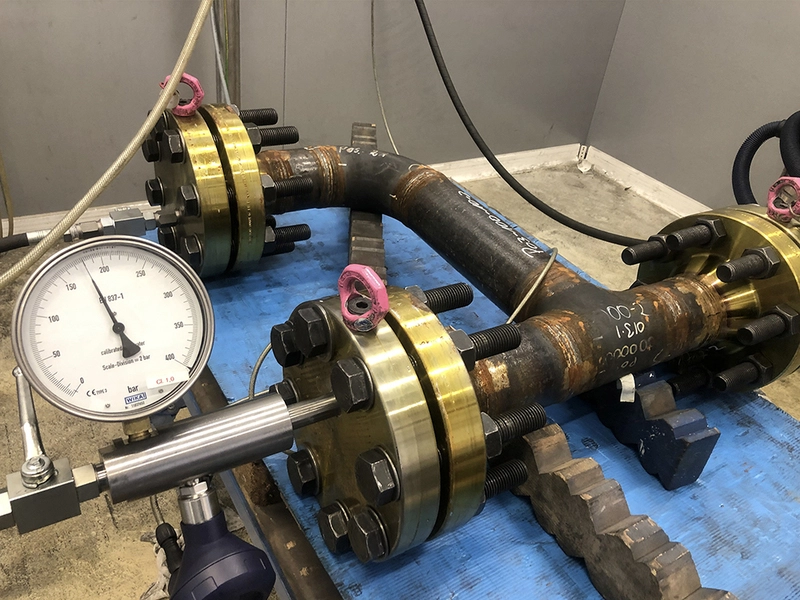

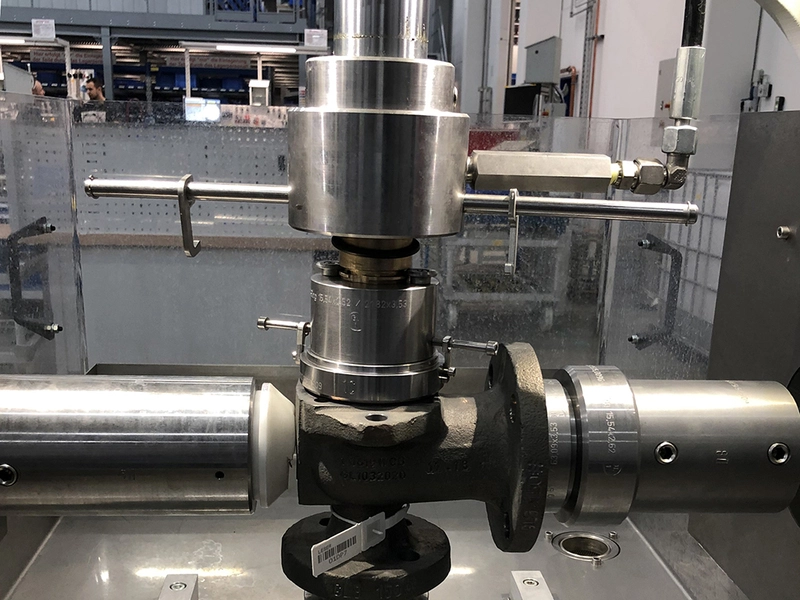

A pressure test is a non-destructive testing method used to check the integrity of a pressure vessel, pipeline, or other pressurized system. The pressure test involves pressurizing the system to a specific pressure level and holding the pressure for a specified period while monitoring for leaks or other signs of failure.

The pressure test is performed to ensure that the system can safely withstand the expected operating pressure without leaking or rupturing. The test is typically performed during the construction or maintenance of the system, or as part of a routine inspection to ensure that the system remains safe and reliable over time.

There are several types of pressure tests, including:

- Hydrostatic pressure test: This method involves filling the system with water or another suitable liquid and pressurizing the system to a predetermined level using a pump. The pressure is held for a specified period, and the system is inspected for leaks or other signs of failure.

- Pneumatic pressure test: This method involves pressurizing the system with air or another gas instead of liquid. Pneumatic pressure tests are often used for systems that cannot be filled with liquid, such as gas pipelines.

- Vacuum pressure test: This method involves creating a vacuum inside the system and measuring the pressure drop over time to detect leaks or other defects.

- Burst pressure test: This test involves pressurizing the system until it fails, either through rupture or other types of failure. Burst pressure tests are typically used for critical systems or components that must meet very high safety standards.

The specific pressure test method used will depend on the type of system being tested, the intended use of the system, and the safety standards that must be met. Pressure tests are typically performed according to industry standards and regulations, and the results of the test are documented to ensure that the system meets the required safety and performance standards.

In conclusion, pressure testing is a critical non-destructive testing method used to ensure the safety and reliability of pressurized systems. By testing the system’s ability to withstand pressure, it can prevent catastrophic failures and ensure that the system operates safely and reliably over time.

For further inquiries, please feel free to Contact Us.