The Significance of Material Testing: Evaluating Properties and Ensuring Quality and Compliance

Material testing is a critical process that involves evaluating the properties, composition, and characteristics of a material. It is used to determine whether the material meets the required specifications, quality standards, and regulatory requirements. Material testing plays a crucial role in ensuring the reliability, safety, and performance of various products and components across different industries.

Material testing encompasses a wide range of techniques and methods, depending on the specific properties and attributes of the material being tested. Some common types of material tests include:

- Mechanical testing: This involves assessing the mechanical properties of a material, such as its strength, hardness, elasticity, ductility, and toughness. Mechanical tests can help determine whether a material is suitable for its intended application and provide insights into its behavior under different loading conditions.

- Chemical analysis: Chemical testing is used to identify and quantify the chemical composition of a material. It helps determine the presence and concentration of various elements, compounds, or impurities, which can have significant impacts on the material’s properties and performance.

- Physical testing: Physical tests involve evaluating the physical characteristics of a material, such as its density, thermal conductivity, electrical conductivity, or magnetic properties. These tests provide valuable information about how the material will behave under different environmental conditions.

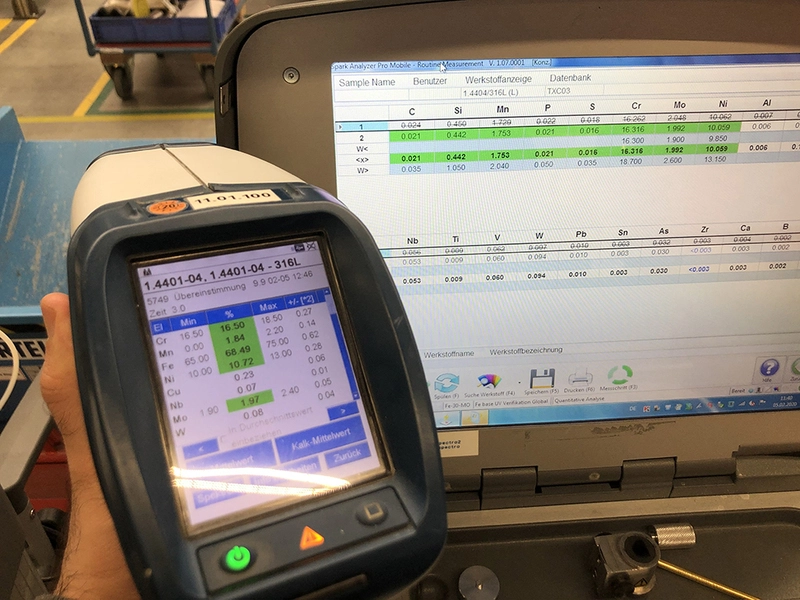

- Non-destructive testing (NDT): NDT methods are employed to assess the integrity and quality of a material or component without causing any permanent damage. Positive Material Identification (PMI) is a non-destructive testing method used to identify the chemical composition of a material, particularly in metal alloys. PMI is typically performed using handheld analyzers or portable X-ray fluorescence (XRF) devices. In this method the device analyze the material’s elemental composition and determine the presence and percentages of various elements.

PMI is commonly employed in industries where the use of correct materials is critical, such as construction, manufacturing, aerospace, and petrochemicals. It helps ensure that the materials used meet the required specifications, prevent material mix-ups, verify the authenticity of materials, and mitigate the risk of using incorrect or substandard alloys.

Please feel free to contact us for any further inquiries or to discuss our services.