Non-Destructive Testing with Magnetic Particle Testing (MT): Uncovering Hidden Discontinuities

Magnetic Particle Testing (MT) is a non-destructive testing (NDT) method used to detect surface and slightly subsurface discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and some of their alloys. The technique involves the use of magnetic fields and magnetic particles to detect flaws.

In the EPC projects involving steel structures and pipes, MT can be used to detect surface-breaking and slightly subsurface cracks, porosity, laps, seams, and other discontinuities in welds and parent materials. The method is useful for detecting defects in hard-to-reach areas and can be performed on both flat and curved surfaces.

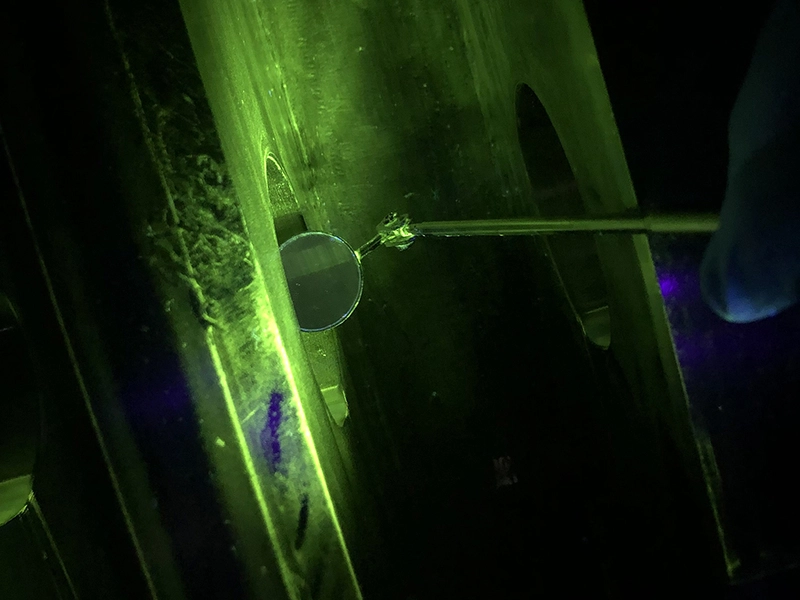

The MT method works by inducing a magnetic field in the test piece, which attracts magnetic particles to any areas of flux leakage caused by a defect. The particles form an indication, which can be seen under UV light or white light, depending on the type of particles used. The size and shape of the indication provide information about the size, shape, and orientation of the defect.

MT can be performed using either dry or wet methods. The dry method involves applying the magnetic particles directly to the surface, while the wet method involves suspending the particles in a liquid that is then applied to the surface. Both methods have their advantages and disadvantages, depending on the specific application.

ITNOG staff are highly trained and skilled in performing magnetic particle testing (MT) in accordance with various industry standards, including:

- ASTM E709: Standard Guide for Magnetic Particle Testing

- ASME Section V: Nondestructive Examination

- ISO 9934-2: Non-destructive testing — Magnetic particle testing — Part 2: Detection media

- EN 1290: Non-destructive testing — Magnetic particle testing — General principles

Our staff can conduct MT on a wide range of ferromagnetic materials, including steel structures and pipes, to detect surface and slightly subsurface discontinuities such as cracks and other defects. We use state-of-the-art equipment and techniques to ensure accurate and reliable results.

At ITNOG, we also offer MT training courses to help individuals and organizations develop their skills and knowledge in this important nondestructive testing method. To learn more about our training programs, please visit the Training Courses page on our website, or feel free to contact us for further information.