Ensuring Safety and Reliability of Pressurized Components in Leakage Testing (LT)

Leakage Testing (LT) is a non-destructive testing method that is used to detect and locate leaks in pressurized components such as pipelines, tanks, and vessels. ITNOG provides Leakage Testing services to ensure the safety and reliability of your equipment.

Our team of experienced professionals is trained to conduct LT using different techniques such as:

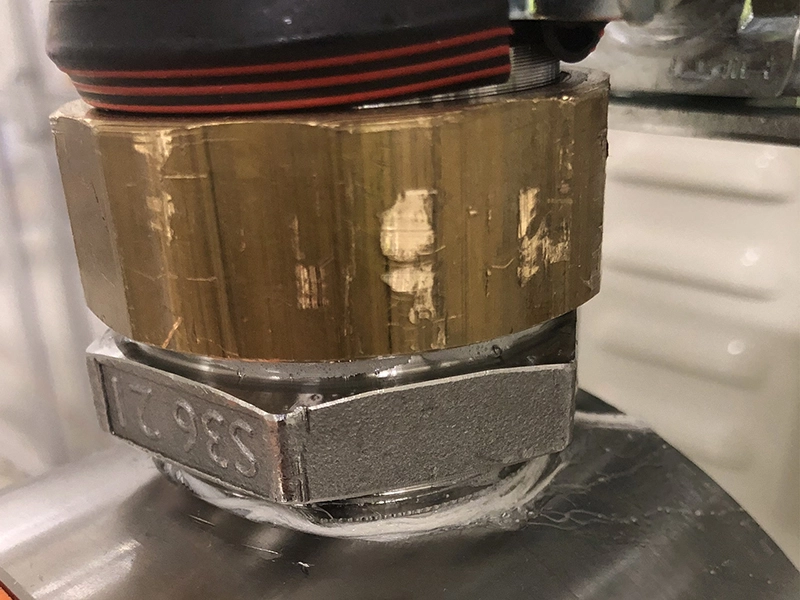

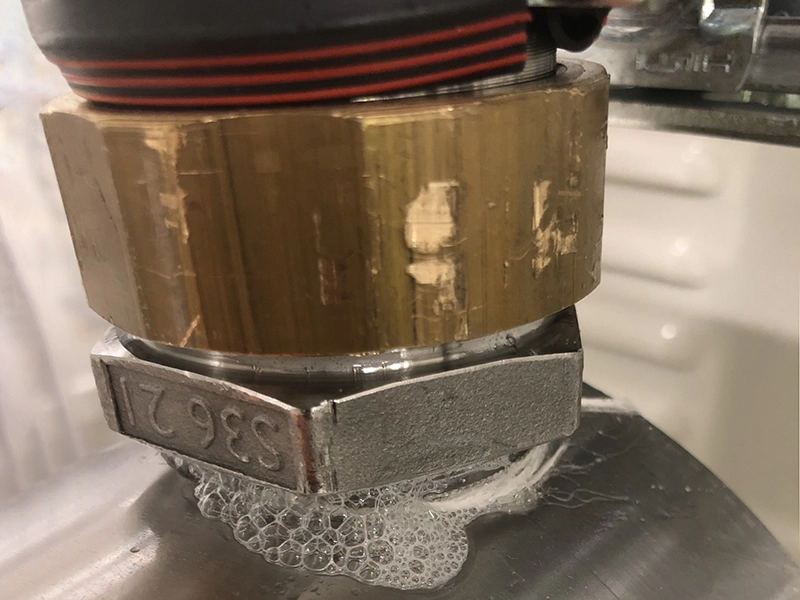

- Bubble Testing: This technique involves applying a soap solution to the surface of the component under test and pressurizing it. If there is a leak, bubbles will form at the location of the leak.

- Pressure Change Testing: This technique involves pressurizing the component under test and monitoring its pressure for a specified period. A pressure drop indicates the presence of a leak.

- Tracer Gas Testing: This technique involves injecting a small amount of tracer gas (such as helium) into the component under test and then using a gas detector to locate the source of the leak.

- Vacuum Testing: This technique involves applying a vacuum to the component under test and monitoring it for a specified period. If there is a leak, air will enter the component, and the vacuum level will drop.

ITNOG can perform LT in accordance with various industry standards, including ISO, ASME, API, and ASTM. Our team is equipped with state-of-the-art equipment to provide accurate and reliable results. Contact us to learn more about our Leakage Testing services.