Safeguarding System Integrity with Leakage Testing (LT)

Leakage testing (LT) is a non-destructive testing method used to detect and locate leaks or defects in a sealed or pressurized system. Leakage testing is a critical process in industries where the failure of a sealed system can have serious consequences, such as the oil and gas industry, chemical plants, and pharmaceutical manufacturing.

There are several types of leakage testing methods, including:

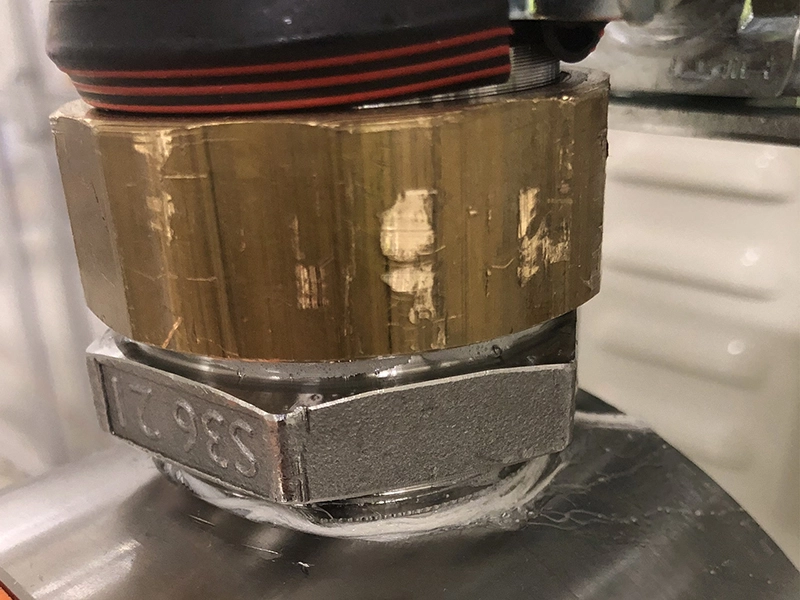

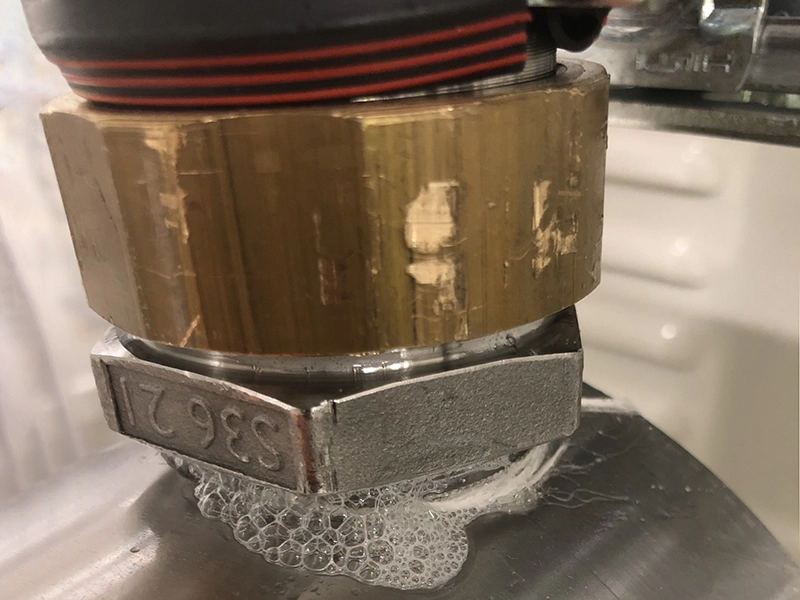

- Bubble testing: This is a simple and low-cost method of detecting leaks by applying a soapy solution to the surface of the sealed system and looking for bubbles. This method is often used for detecting small leaks in low-pressure systems.

- Pressure decay testing: This method involves pressurizing the system and then monitoring the pressure drop over time to detect leaks. The pressure decay test is a sensitive and reliable method for detecting leaks in both high and low-pressure systems.

- Vacuum testing: This method involves creating a vacuum within the sealed system and then monitoring the vacuum level to detect leaks. Vacuum testing is often used for detecting leaks in systems that cannot be pressurized.

- Mass spectrometry testing: This method involves injecting a tracer gas into the sealed system and then using a mass spectrometer to detect any leaks. Mass spectrometry testing is a highly sensitive method for detecting very small leaks.

The type of leakage testing method used will depend on the type of system being tested, the required sensitivity, and the available resources. Leakage testing is typically performed during the manufacturing process, after maintenance or repairs, or as part of routine inspections to ensure the integrity of the sealed system.

In conclusion, leakage testing is an essential non-destructive testing method used to ensure the safety and reliability of sealed or pressurized systems. By detecting and locating leaks early, it can prevent costly and dangerous failures and ensure that the system operates as intended.

In ITNOG, we are satisfying our clients with the Leakage test method of their interest. For further inquiries or to learn more about our industrial services, please feel free to Contact Us. Our team of experts is available to assist you and provide the information you need.