Dimensional Checks: A Critical Step in Manufacturing and Quality Assurance

Dimensional check is a process used to verify that the dimensions of a product or component are within specified tolerances and conform to design requirements. This is typically done during manufacturing or production to ensure that the product is made correctly and meets the customer’s specifications.

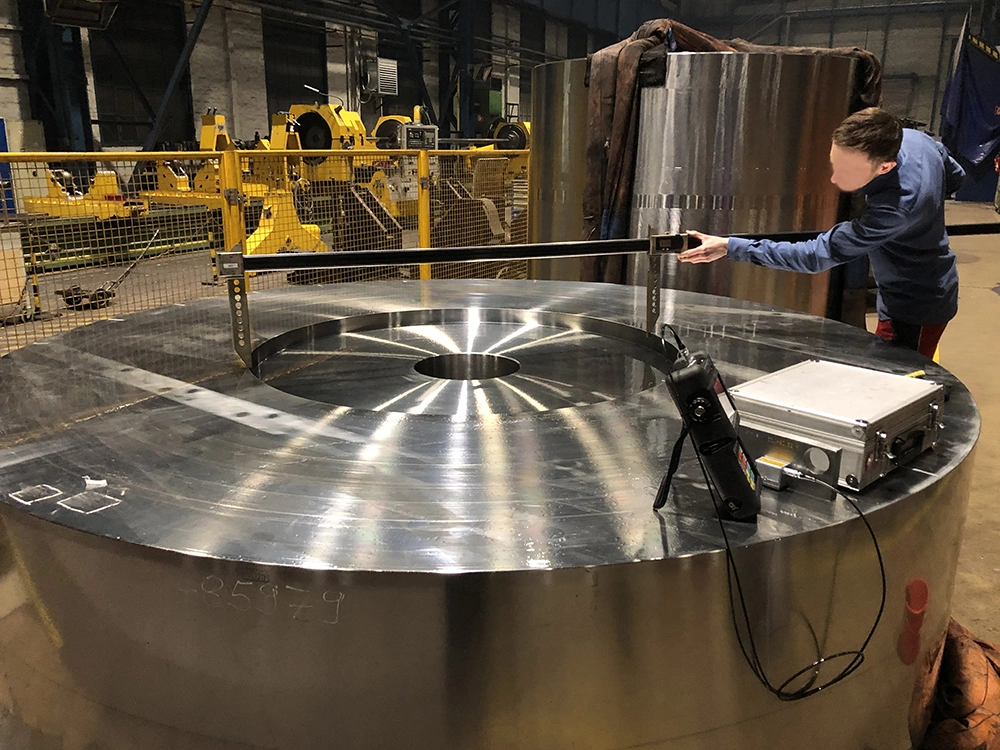

Dimensional checks involve measuring the dimensions of a product or component using various measurement tools and techniques, such as micrometers, calipers, height gauges, and coordinate measuring machines (CMMs). The measurements are compared to the design specifications and tolerances to determine whether the product is within acceptable limits.

The dimensional check process typically involves several steps, including selecting the appropriate measurement tools, establishing the reference points and datum features, taking the measurements, and analyzing the results. The results are typically recorded in a dimensional report that summarizes the measurements and any deviations from the design specifications.

Dimensional checks are critical to ensuring the quality and accuracy of manufactured products. If the dimensions of a product are out of tolerance, it can affect its performance, functionality, and safety. Therefore, dimensional checks are performed at various stages of the production process, including in-process checks, final inspection, and during routine quality control checks to ensure that the product meets the required standards and specifications.

For further inquiries, please feel free to Contact Us.