Coating Inspection: Ensuring Quality and Performance of Protective Coatings

Inspection of coatings is a critical aspect of ensuring the quality and performance of protective coatings applied to various substrates, such as metal, concrete, or wood. One of the key parameters that are checked during coating inspection is the dry film thickness (DFT) of the coating.

DFT is a measure of the thickness of the coating after it has dried and cured. The thickness of the coating is critical to its performance because a coating that is too thin may not provide adequate protection, while a coating that is too thick may be prone to cracking, peeling, or delamination. The DFT is typically measured using a dry film thickness gauge, which is a non-destructive testing tool that measures the thickness of the coating without damaging it.

The DFT gauge works by using magnetic or eddy current principles to measure the distance between the gauge’s probe and the substrate’s surface. The DFT gauge provides a readout of the thickness of the coating in mils or microns, allowing the inspector to compare the measured thickness to the specified DFT range for the coating.

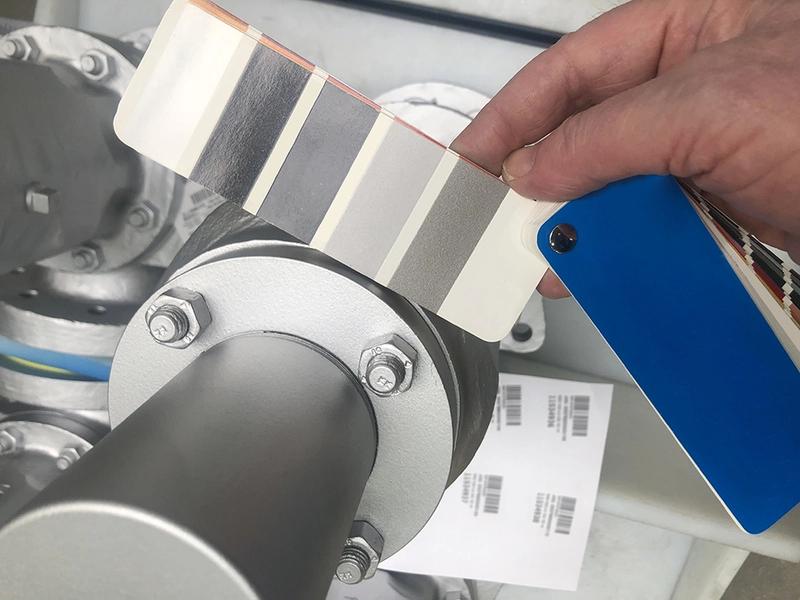

During coating inspection, the inspector may also check other coating parameters, such as adhesion, color, gloss, and surface profile. Adhesion testing measures the strength of the bond between the coating and the substrate, while color and gloss measurements ensure that the coating meets the visual requirements of the specification. Surface profile testing is performed to ensure that the coating has been applied uniformly and that it provides the required surface roughness for optimal adhesion.

Overall, inspection of coatings, including DFT testing, is an essential step in ensuring the quality and performance of protective coatings. Regular inspection and testing can help identify any defects or issues with the coating before they become major problems, allowing for timely corrective action to be taken and ensuring that the coating provides the required protection and durability.

For further inquiries, please feel free to Contact Us.